Code

HCS25241

Weight

6 Kg / 13.23 lbs

Size

Height

46cm (18") Width

29cm (11") Depth

23cm (9") Material

Copper

Availability

Available

Safe Payment

We accept Paypal, Money Transfer, Bank Transfer

Confidence

Protection covers your purchase and personal data.

Worldwide Delivery

We ship Worldwide, except Russia.Shipping cost US$25.2 for upto 0.5 kgs

Hotline

Talk to help line for your question on 9841267335Partly Gold plating.

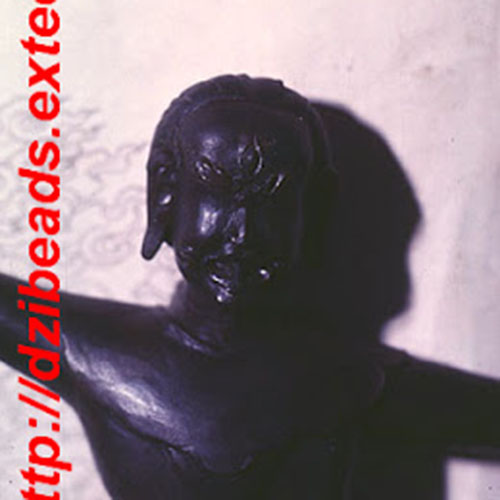

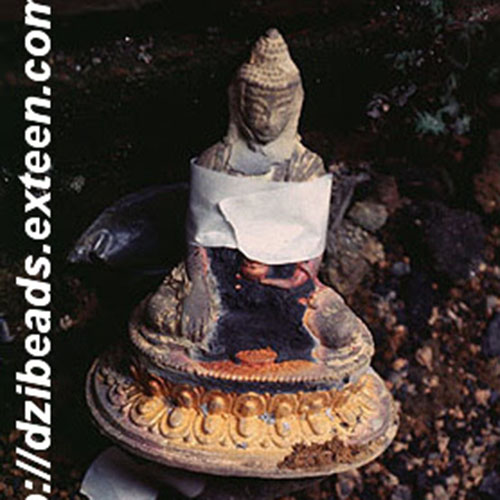

This [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] has a Partly gold-plated finish. Partly fire gold gilding, a common practice in Nepali handicrafts. This technique is skillfully employed by artisans to create intricate designs on various metal objects, including statues, jewelry, and decorative items. Through a process, a mask or resist is applied to safeguard specific areas from the gold plating. The object is then subjected to high temperatures, allowing the gold to beautifully adhere to exposed surfaces using a combination of heat and pressure.

In the realm of Buddhist statues, this technique holds additional significance as it distinguishes the golden-plated body from the oxidized or maroon-painted clothing. This visual separation conveys the contrast between the divine purity of the body and the modest attire symbolizing the humble lifestyle of Buddhist monks. The partly fire gold gilding not only adds exquisite detail and elegance but also embodies the deep cultural and spiritual meaning associated with these treasured artifacts. Read More . . .

This [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] has a Partly gold-plated finish. Partly fire gold gilding, a common practice in Nepali handicrafts. This technique is skillfully employed by artisans to create intricate designs on various metal objects, including statues, jewelry, and decorative items. Through a process, a mask or resist is applied to safeguard specific areas from the gold plating. The object is then subjected to high temperatures, allowing the gold to beautifully adhere to exposed surfaces using a combination of heat and pressure.

In the realm of Buddhist statues, this technique holds additional significance as it distinguishes the golden-plated body from the oxidized or maroon-painted clothing. This visual separation conveys the contrast between the divine purity of the body and the modest attire symbolizing the humble lifestyle of Buddhist monks. The partly fire gold gilding not only adds exquisite detail and elegance but also embodies the deep cultural and spiritual meaning associated with these treasured artifacts. Read More . . .

Finishing: Stone Setting

The [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] is adorned with an exquisite array of semi-precious stones, including turquoise, coral, and lapis lazuli. These stones are carefully selected and meticulously placed on the [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]'s surface, adding a touch of opulence and enhancing its overall beauty. Each stone is thoughtfully positioned using a high-quality adhesive, ensuring secure and long-lasting attachment. The vibrant colors and unique patterns of the stones create a captivating contrast against the backdrop of the [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style], elevating its visual appeal and making it truly eye-catching. Read More . . .

The [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] is adorned with an exquisite array of semi-precious stones, including turquoise, coral, and lapis lazuli. These stones are carefully selected and meticulously placed on the [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]'s surface, adding a touch of opulence and enhancing its overall beauty. Each stone is thoughtfully positioned using a high-quality adhesive, ensuring secure and long-lasting attachment. The vibrant colors and unique patterns of the stones create a captivating contrast against the backdrop of the [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style], elevating its visual appeal and making it truly eye-catching. Read More . . .

About Color Finishing

The [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] is adorned with traditional colors, creating a captivating aesthetic through a combination of gold and various hues. This painting technique follows a time-honored process that aims to faithfully represent the [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] in accordance with traditional color descriptions. In the context of Buddhist statues, this approach holds great significance. Each statue has its own primary color, and it is crucial to depict the statue in its authentic shade. Read More . . .

The [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] is adorned with traditional colors, creating a captivating aesthetic through a combination of gold and various hues. This painting technique follows a time-honored process that aims to faithfully represent the [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] in accordance with traditional color descriptions. In the context of Buddhist statues, this approach holds great significance. Each statue has its own primary color, and it is crucial to depict the statue in its authentic shade. Read More . . .

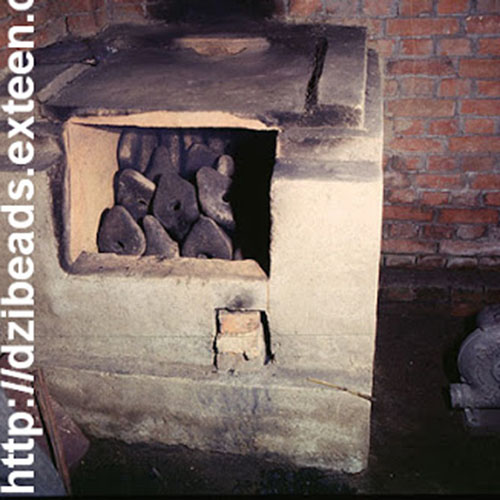

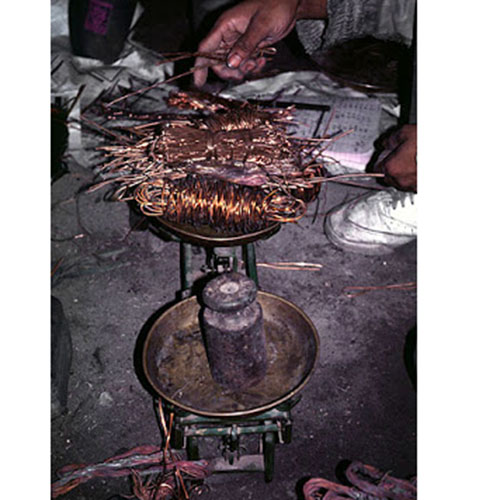

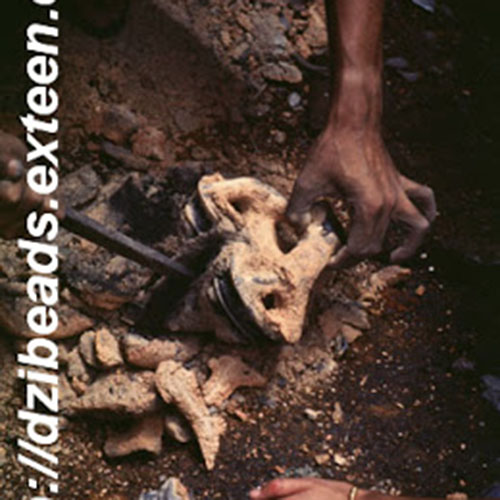

Lost-Wax System

This Tara of [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Tara.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

This Tara of [master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Tara.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

Brief Introduction :

White Tara is a revered figure in Buddhist mythology, often depicted as a compassionate and serene goddess. She embodies peace and emanates loving compassion, bringing grace and dignity to various situations. White Tara's presence encourages the emergence of goodness and positive outcomes in all circumstances. She upholds the Four Measureless States, which include Loving Kindness, Compassion, Sympathetic Joy, and Equanimity, encompassing past, present, and future circumstances. Additionally, White Tara is associated with the bestowing of longevity, symbolizing a long and healthy life. Her essence embodies the ideals of compassion and benevolence, making her a significant figure in Buddhist worship and spiritual practices.

Iconography :Sita Tara, popularly known as White Tara. She has emanated from Avalokiteshvara & in the Nepali Transcendent Buddha tradition is the consort of Vairochana, the central Transcendent Buddha. Her inner virtue of loving compassion is magnified by the simplicity of her presentation. White Tara is an important Vajrayana Buddhist figure since she embodies the principle of loving kindness, which is the central quality in the altruistic Bodhisattva presented through Mahayana Buddhism. Her main emblem is the Pink Lotus [Skt. Kamala] representing this main quality.

Her left hand is gracefully lowered in an empty open palm boon granting gesture [Skt. Varada Mudra]. White Tara has a blooming pink lotus & an unopened bud on either side of her body. The lotus in the painting is stylised as a peony & a chrysanthemum to provide artistic contrast with her lotus throne. The open blossom represents the present and the bud represents the future situations & Buddhas yet to be born. The future also refers to beneficial changes circumstances that she will help bring about. Her right hand wisdom hand is in the gesture of giving refuge [Skt. Sharanagamana]. The word refuge refers to the teaching of compassionate understanding which she imparts. The third finger touches the thumb to create a circle representing the union of wisdom and compassion, and the three extended fingers symbolise the Three Jewels of Buddhism A. The Buddha State B. The Body of teachings [Skt. Sangha] C. The Principles of the Universal form [Skt. Dharma]. The same hand holds the stem of a blue lotus [Skt. Utpala] representing change. The lower part of the stem below the bend represents the root of the lotus in the mud. The allegory of the Lotus refers to the something that grows from the obscurity of the mud & which eventually bursts open in the light. The lotus journey is one of inner awakening & enlightenment analogous to the human spirit. Buddhism shows us how to grow towards the light with profound teachings which help us to navigate away from burdens and sufferings which we may have by being materially minded, bitter & confused.

There is a lotus on her diadem bearing the Wish Granting Gem [Skt. Chintamani] surrounded by an aureole of fire symbolising auspicious blessings. The extra eye on her forehead, on the palms of her hands & soles of her feet represent her ability to see and understand the sufferings of all beings & her omniscient compassion toward the suffering. Avalokiteshvara [Tib. Chengresi] her progenitor also has a white body & extra eyes. The eyes denote psychic & supernatural power. The rainbow coloured leggings represent a mastery of Boddhi Nature [Skt. Siddhi] & a manifestation of the Sambhogakaya. The dark blue layer of clothing signifies Mantrayana practice. She is upon a white moon disk & has an orange sun aureole to representing her emanation their melting point [Skt. Nada]. There is a branch of an Ashoka Tree in the foreground. The word Ashoka means 'without sorrow' in other words she has no regrets about her behaviour. The tree linked to the Vedic God of love & sexual union Kamadeva which blossoms when a virtuous lady touches it. The triangular diamond rock formation in the foreground represents the Source of Reality [Skt. Dharmadaya] out of which deities arise & which is generated from emptiness by the seed syllable E. In the Indian language is a Triangular shaped letter D & so expressed in the triangular rock formations.

Commentary :Her left hand is gracefully lowered in an empty open palm boon granting gesture [Skt. Varada Mudra]. White Tara has a blooming pink lotus & an unopened bud on either side of her body. The lotus in the painting is stylised as a peony & a chrysanthemum to provide artistic contrast with her lotus throne. The open blossom represents the present and the bud represents the future situations & Buddhas yet to be born. The future also refers to beneficial changes circumstances that she will help bring about. Her right hand wisdom hand is in the gesture of giving refuge [Skt. Sharanagamana]. The word refuge refers to the teaching of compassionate understanding which she imparts. The third finger touches the thumb to create a circle representing the union of wisdom and compassion, and the three extended fingers symbolise the Three Jewels of Buddhism A. The Buddha State B. The Body of teachings [Skt. Sangha] C. The Principles of the Universal form [Skt. Dharma]. The same hand holds the stem of a blue lotus [Skt. Utpala] representing change. The lower part of the stem below the bend represents the root of the lotus in the mud. The allegory of the Lotus refers to the something that grows from the obscurity of the mud & which eventually bursts open in the light. The lotus journey is one of inner awakening & enlightenment analogous to the human spirit. Buddhism shows us how to grow towards the light with profound teachings which help us to navigate away from burdens and sufferings which we may have by being materially minded, bitter & confused.

There is a lotus on her diadem bearing the Wish Granting Gem [Skt. Chintamani] surrounded by an aureole of fire symbolising auspicious blessings. The extra eye on her forehead, on the palms of her hands & soles of her feet represent her ability to see and understand the sufferings of all beings & her omniscient compassion toward the suffering. Avalokiteshvara [Tib. Chengresi] her progenitor also has a white body & extra eyes. The eyes denote psychic & supernatural power. The rainbow coloured leggings represent a mastery of Boddhi Nature [Skt. Siddhi] & a manifestation of the Sambhogakaya. The dark blue layer of clothing signifies Mantrayana practice. She is upon a white moon disk & has an orange sun aureole to representing her emanation their melting point [Skt. Nada]. There is a branch of an Ashoka Tree in the foreground. The word Ashoka means 'without sorrow' in other words she has no regrets about her behaviour. The tree linked to the Vedic God of love & sexual union Kamadeva which blossoms when a virtuous lady touches it. The triangular diamond rock formation in the foreground represents the Source of Reality [Skt. Dharmadaya] out of which deities arise & which is generated from emptiness by the seed syllable E. In the Indian language is a Triangular shaped letter D & so expressed in the triangular rock formations.

Tara's are difficult to place being neither Deity nor Dakini. Tara's are commonly described as female emanations and aides of Buddhas. Deities tend to have consorts with whom they are having sexual intercourse. She has a special association with the Pink lotus which represents the arising of wisdom from the obscure depths of the mud and the flowering of the awoken wisdom. The mud symbolised the primeval state. As with the other emanations of Tara, she has come into being from the teardrop of Avalokateshwara the great Bodhisattva of compassion.

Mantra of White Tara

Om Tare Tuttare Ture Mama Ayuh Punya Jñana Pustim Kuru Svaha

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_2.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_3.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_4.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_5.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_6.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_0.jpg)

![[master Quality],buddhist Statue Of White Tara, [traditional Color, Partly Gold Plated, Stone Setting], [museum Style]](https://handicraftseller.com/uploads/pics/product/thumb/2022/03/25241_1.jpg)

Green Tara, Buddhist Handmade Statue,

Green Tara, Buddhist Handmade Statue,  Green Tara, Buddhist Handmade Statue,

Green Tara, Buddhist Handmade Statue,  Green Tara, Buddhist Handmade Statue

Green Tara, Buddhist Handmade Statue  Green Tara, Buddhist Handmade Statue

Green Tara, Buddhist Handmade Statue  of Green Tara,

of Green Tara,  of Green Tara,

of Green Tara,  Green Tara, Buddhist Handmade Statue,

Green Tara, Buddhist Handmade Statue,  Green Tara, Buddhist Handmade Statue,

Green Tara, Buddhist Handmade Statue,  Master Quality, Buddhist Statue

Master Quality, Buddhist Statue  Master Quality, Buddhist Statue

Master Quality, Buddhist Statue  Green Tara, Buddhist Handmade Statue,

Green Tara, Buddhist Handmade Statue,  Green Tara, Buddhist Handmade Statue,

Green Tara, Buddhist Handmade Statue,  of Nataraj,

of Nataraj,  of Nataraj,

of Nataraj,  Newari Museum Copy, Buddhist Statue

Newari Museum Copy, Buddhist Statue  Newari Museum Copy, Buddhist Statue

Newari Museum Copy, Buddhist Statue  High Quality, Tibetan Buddhist Handmade Statue

High Quality, Tibetan Buddhist Handmade Statue  High Quality, Tibetan Buddhist Handmade Statue

High Quality, Tibetan Buddhist Handmade Statue  Green Tara Buddhist Handmade Large Statue - Featuring Natural Patina" title="

Green Tara Buddhist Handmade Large Statue - Featuring Natural Patina" title=" Green Tara Buddhist Handmade Large Statue - Featuring Natural Patina" title="

Green Tara Buddhist Handmade Large Statue - Featuring Natural Patina" title="