Code

HCS22519

Weight

774 gm / 1.71 lbs

Size

Height

14cm (6") Width

11cm (4") Depth

6cm (2") Material

Sterling Silver

Availability

Available

Date Added

2021-01-17 00:52:32

Note : We used to sell this product 4 years ago so it may no longer be in our stock.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

Safe Payment

We accept Paypal, Money Transfer, Bank Transfer

Confidence

Protection covers your purchase and personal data.

Worldwide Delivery

We ship Worldwide, except Russia.Shipping cost US$25.2 for upto 0.5 kgs

Hotline

Talk to help line for your question on 9841267335Master Quality : What is master Quality?

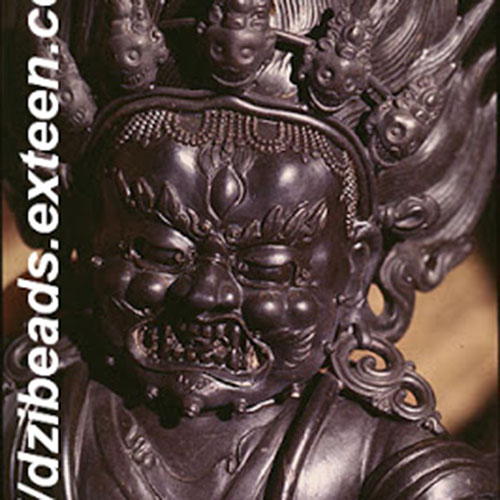

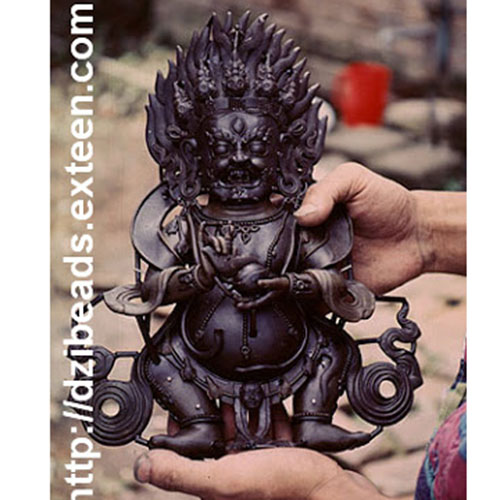

The attribute of "master quality" distinguishes the [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] as an embodiment of extraordinary craftsmanship and artistic excellence. This exceptional piece is directly handcrafted by an artist or craftsman of the highest categorization, reflecting their unparalleled skill and expertise. The uniqueness of [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] lies in its exclusivity to the artist, making it a rare find with nearly impossible chances of finding an identical piece in the same category. While copies may exist, they can never truly replicate the essence of the original, as an artist or craftsman capable of creating such exceptional artistry would prefer to showcase their own creative vision rather than reproduce another's work. Read More . . .

The attribute of "master quality" distinguishes the [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] as an embodiment of extraordinary craftsmanship and artistic excellence. This exceptional piece is directly handcrafted by an artist or craftsman of the highest categorization, reflecting their unparalleled skill and expertise. The uniqueness of [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] lies in its exclusivity to the artist, making it a rare find with nearly impossible chances of finding an identical piece in the same category. While copies may exist, they can never truly replicate the essence of the original, as an artist or craftsman capable of creating such exceptional artistry would prefer to showcase their own creative vision rather than reproduce another's work. Read More . . .

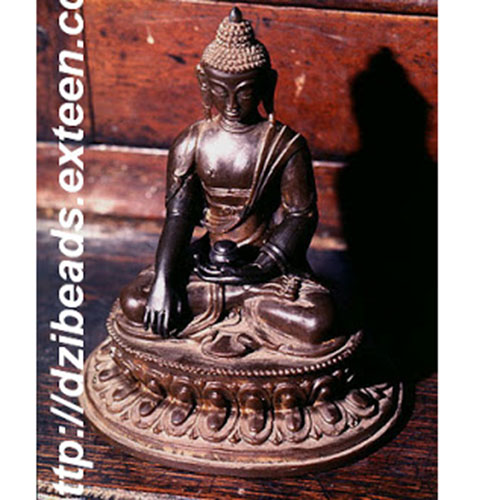

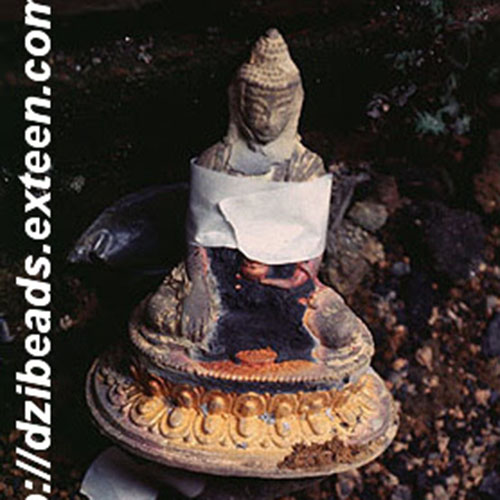

Silver Statue : About Silver Statue:

The Silver Statues are rarely made these days, This [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] statue date back to the late 1990 A.D. Most of the statues in our collection are highly collectibles because the silver statues were rarely found even though the prices were cheap during the late 1990 and early 2000. In this present era, the price of silver has hicked so much that making a silver statue for a commercial purpose is not viable anymore. The price we have offered for the statues are comparatively than of making a new one.

The Silver Statues are rarely made these days, This [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] statue date back to the late 1990 A.D. Most of the statues in our collection are highly collectibles because the silver statues were rarely found even though the prices were cheap during the late 1990 and early 2000. In this present era, the price of silver has hicked so much that making a silver statue for a commercial purpose is not viable anymore. The price we have offered for the statues are comparatively than of making a new one.

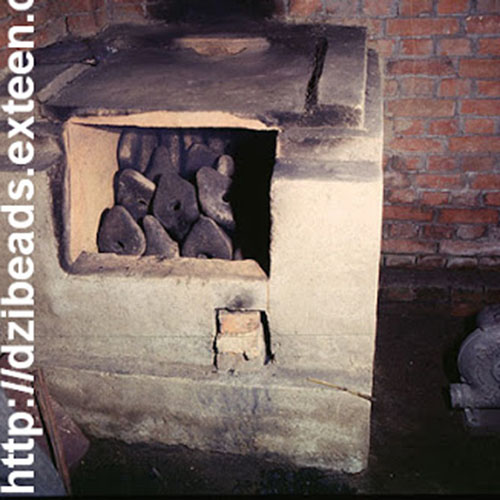

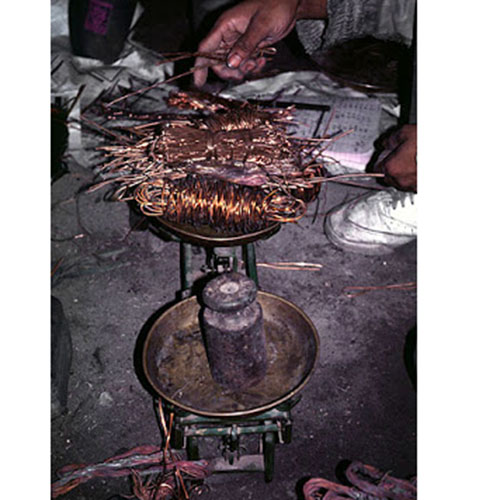

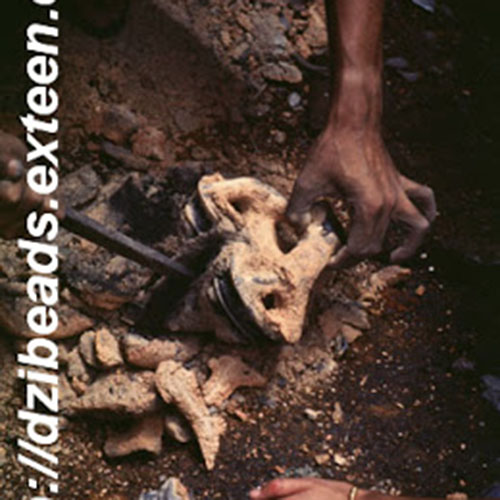

Lost-Wax System

This Silver Statue of [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Silver Statue.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

This Silver Statue of [master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Silver Statue.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

Brief Introduction :

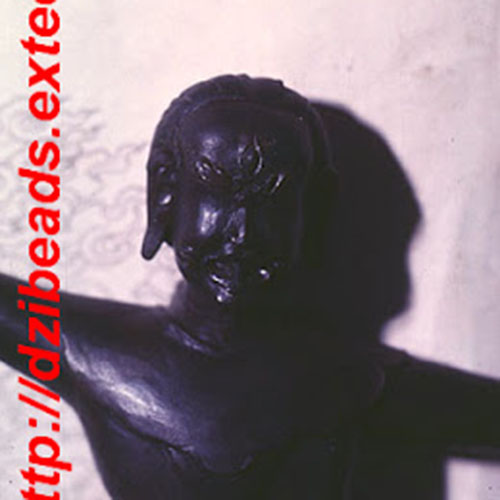

Vajrapaṇi is one of the earliest bodhisattvas of Mahayana Buddhism. He is the protector and guide of the Buddha, and rose to symbolize the Buddha's power. Vajrapani was used extensively in Buddhist iconography as one of the three protective deities surrounding the Buddha. Each of them symbolizes one of the Buddha's virtues: Manjusri (the manifestation of all the Buddhas' wisdom), Avalokitesvara (the manifestation of all the Buddhas' compassion) and Vajrapani (the manifestation of all the Buddhas' power). Furthermore, Vajrapani is one of the earliest Dharmapalas and one of the rare Buddhist deities to be worshiped in the original Zen Buddhism of the Shaolin Temple, Tibetan Buddhism, and even Pure Land Buddhism (where he is known as Mahasthamaprapta). Manifestations of Vajrapani can also be found in many Buddhist temples in Japan as Dharma protectors called Nio.

Iconography :Vajrapani is pictured dancing wildly within a halo of flames, which represent transformation.

He holds a vajra (thunderbolt) in his right hand, which emphasizes the power to cut through the darkness of delusion. Vajrapani looks wrathful, but as a representation of the enlightened mind, heâs completely free from hatred.

Vajrapaniâs mantra is simply his name, which means "wielder of the thunderbolt", framed between the mystical syllables Om and Hūm. This mantra helps us to gain access to the irrepressible energy that Vajrapani symbolizes. A familiarity with Vajrapani does, of course, help here, although the sound of the mantra is itself rather energetic.

Mantra :He holds a vajra (thunderbolt) in his right hand, which emphasizes the power to cut through the darkness of delusion. Vajrapani looks wrathful, but as a representation of the enlightened mind, heâs completely free from hatred.

Vajrapaniâs mantra is simply his name, which means "wielder of the thunderbolt", framed between the mystical syllables Om and Hūm. This mantra helps us to gain access to the irrepressible energy that Vajrapani symbolizes. A familiarity with Vajrapani does, of course, help here, although the sound of the mantra is itself rather energetic.

The Mantra oṃ vajrapāṇi hūṃ phaṭ is associated with Vajrapani. His Seed Syllable is hūṃ.

Matra of Vajrapani

oṃ va jra pā ṇi hūṃ

oṃ vajrapāṇi hūṃ

oṃ vajrapāṇi hūṃ

![[master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock]](https://handicraftseller.com/uploads/pics/product/thumb/2021/01/22519.jpg)

![[master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock]](https://handicraftseller.com/uploads/pics/product/thumb/2021/01/22519_0.jpg)

![[master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock]](https://handicraftseller.com/uploads/pics/product/thumb/2021/01/22519_1.jpg)

![[master Quality], Sterling Silver, [774 Gram] Statue Of Vajrapani [chana Dorje], [old Stock]](https://handicraftseller.com/uploads/pics/product/thumb/2021/01/22519_2.jpg)

Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver, Decoration Plate,

Master Quality, Sterling Silver, Decoration Plate,  Master Quality, Sterling Silver, Decoration Plate,

Master Quality, Sterling Silver, Decoration Plate,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,  Master Quality, Sterling Silver,

Master Quality, Sterling Silver,