Code

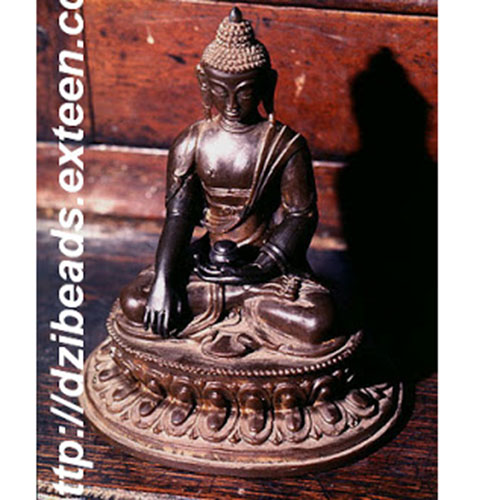

HCS3429

Weight

1.8 Kg / 3.97 lbs

Size

Height

22cm (9") Width

15cm (6") Depth

11cm (4") Material

Copper

Availability

Subject to Avilability

Date Added

2009-07-29 22:23:08

Note : We used to sell this product 16 years ago so it may no longer be in our stock.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

Safe Payment

We accept Paypal, Money Transfer, Bank Transfer

Confidence

Protection covers your purchase and personal data.

Worldwide Delivery

We ship Worldwide, except Russia.Shipping cost US$25.2 for upto 0.5 kgs

Hotline

Talk to help line for your question on 9841267335Old Post : OLD POST

Please note that this Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] is an old post. We typically do not remove our posts from the website for various reasons, such as nostalgia and maintaining page ratings. These posts are not intended for direct sales, but occasionally, we can remake the items.

Please note that this Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] is an old post. We typically do not remove our posts from the website for various reasons, such as nostalgia and maintaining page ratings. These posts are not intended for direct sales, but occasionally, we can remake the items.

Remakable : Remakable

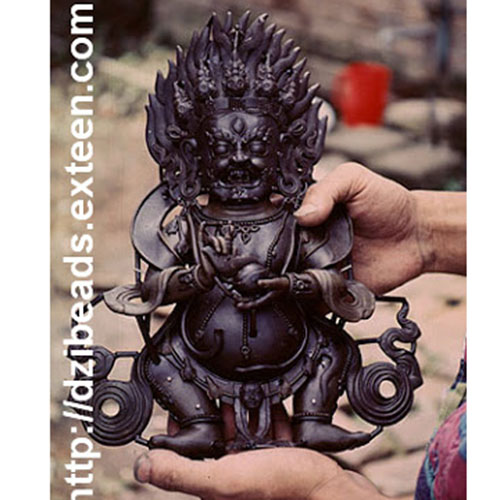

Please note that the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] we posted some time ago is not currently available in our store. However, due to the possibility of a remake, it is still on sale. The remake will not be an exact replica of the original statue shown in the picture and will require additional time to be ready for dispatch. If you are willing to wait for this custom remake, you may proceed with your order. Thank you for your understanding and patience.

Please note that the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] we posted some time ago is not currently available in our store. However, due to the possibility of a remake, it is still on sale. The remake will not be an exact replica of the original statue shown in the picture and will require additional time to be ready for dispatch. If you are willing to wait for this custom remake, you may proceed with your order. Thank you for your understanding and patience.

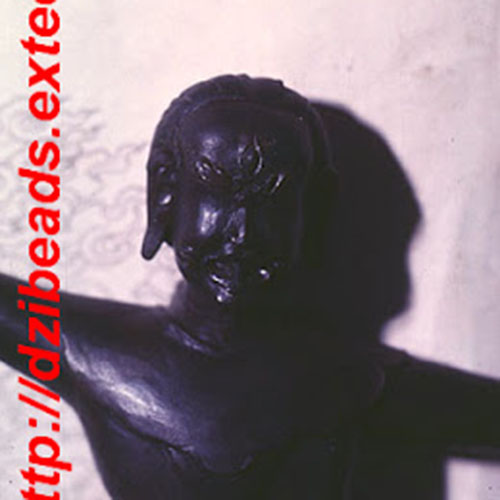

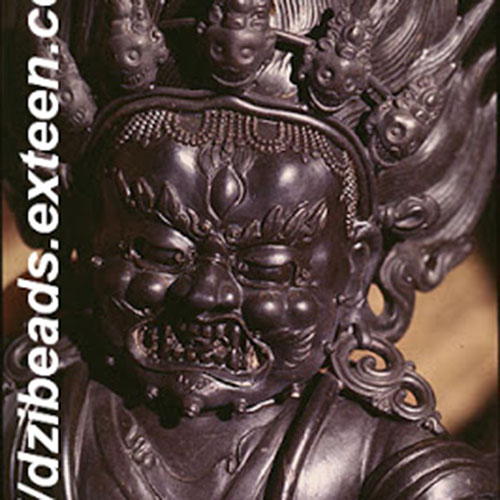

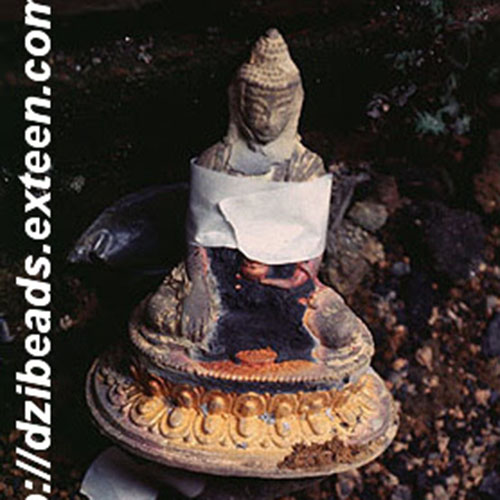

Full Gold Gilded with Antique Patina.

The Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] has full gold plated antique finishing. This finishing is a combination of fire mercury gold plating and antique finishing. This traditional technique involves the application of a genuine layer of gold onto the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] using the time-honored process of mercury gold plating. Skilled artisans meticulously handle the amalgamation of gold with mercury, ensuring precise application and a truly authentic result. To enhance its charm further, the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] undergoes an antique finishing process. This meticulous treatment adds a touch of age and character to the gold plating, creating a sense of antiquity. Through careful craftsmanship and the application of specialized techniques, the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] acquires a beautifully aged appearance that adds depth and uniqueness to its overall aesthetic. Read More . . .

The Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] has full gold plated antique finishing. This finishing is a combination of fire mercury gold plating and antique finishing. This traditional technique involves the application of a genuine layer of gold onto the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] using the time-honored process of mercury gold plating. Skilled artisans meticulously handle the amalgamation of gold with mercury, ensuring precise application and a truly authentic result. To enhance its charm further, the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] undergoes an antique finishing process. This meticulous treatment adds a touch of age and character to the gold plating, creating a sense of antiquity. Through careful craftsmanship and the application of specialized techniques, the Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] acquires a beautifully aged appearance that adds depth and uniqueness to its overall aesthetic. Read More . . .

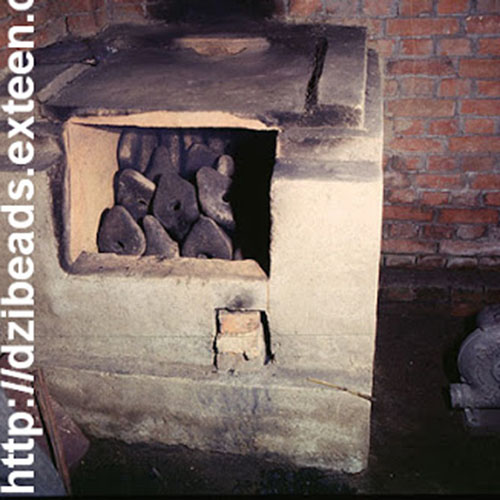

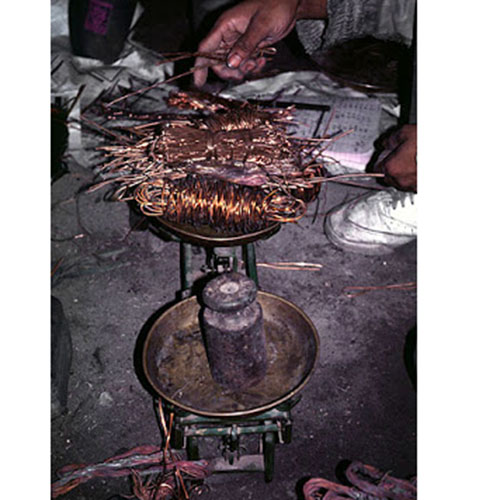

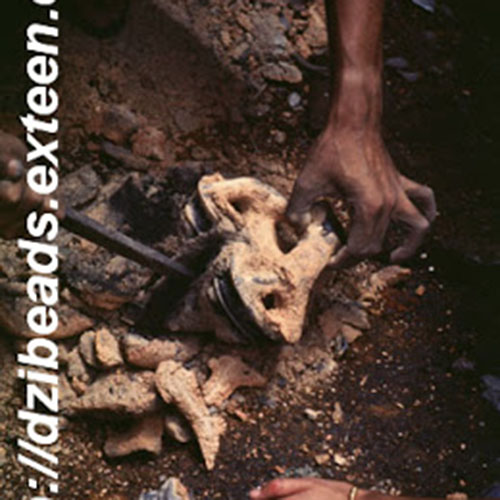

Lost-Wax System

This Buddha of Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Buddha.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

This Buddha of Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Buddha.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

Brief Introduction :

Nagarjuna was an Indian Mahāyāna Buddhist thinker, scholar-saint and philosopher. He is widely considered as one of the most important Buddhist philosophers. Furthermore, according to Jan Westerhoff, he is also "one of the greatest thinkers in the history of Asian philosophy." Nagarjuna is widely considered to be the founder of the madhyamaka school of Buddhist philosophy and a defender of the Mahāyāna movement. His Mulamadhyamakakarika is the most important text on the madhyamaka philosophy of emptiness. The MMK inspired a large number of commentaries in Sanskrit, Chinese, Tibetan, Korean and Japanese and continues to be studied today

life Of Nagarjuna :Very little is reliably known of the life of Nagarjuna and modern historians do not agree on a specific date or place for him. The earliest surviving accounts were written in Chinese and Tibetan centuries after his death and are mostly hagiographical accounts that are historically unverifiable.

Some scholars such as Joseph Walser argue that Nāgārjuna was an advisor to a king of the Sātavāhana dynasty which ruled the Deccan Plateau in the second century. This is supported by most of the traditional hagiographical sources as well. Archaeological evidence at Amarāvatī indicates that if this is true, the king may have been Yajna Sri Satakarni. On the basis of this association, Nagarjuna is conventionally placed at around 150â250 CE.

A model of the Amaravati Stupa

Walser thinks that it is most likely that when Nagarjuna wrote the Ratnavali, he lived in a mixed monastery in which Mahāyānists were the minority. The most likely sectarian affiliation of the monastery according to Walser was Purvasailya, Aparasailya, or Caityaka

He also argues that "it is plausible that he wrote the Ratnavali within a thirty-year period at the end of the second century in the Andhra region around Dhanyakataka (modern-day Amaravati)."

Some scholars such as Joseph Walser argue that Nāgārjuna was an advisor to a king of the Sātavāhana dynasty which ruled the Deccan Plateau in the second century. This is supported by most of the traditional hagiographical sources as well. Archaeological evidence at Amarāvatī indicates that if this is true, the king may have been Yajna Sri Satakarni. On the basis of this association, Nagarjuna is conventionally placed at around 150â250 CE.

A model of the Amaravati Stupa

Walser thinks that it is most likely that when Nagarjuna wrote the Ratnavali, he lived in a mixed monastery in which Mahāyānists were the minority. The most likely sectarian affiliation of the monastery according to Walser was Purvasailya, Aparasailya, or Caityaka

He also argues that "it is plausible that he wrote the Ratnavali within a thirty-year period at the end of the second century in the Andhra region around Dhanyakataka (modern-day Amaravati)."

![Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2009/07/3429_0.jpg)

![Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2009/07/3429_1.jpg)

![Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2009/07/3429_2.jpg)

![Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2009/07/3429_3.jpg)

![Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2009/07/3429_4.jpg)

![Nagarjuna Buddha Statue, [full Gold Plated], Antique Finishing, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2009/07/3429.jpg)

of Shakyamuni Buddha

of Shakyamuni Buddha  of Shakyamuni Buddha

of Shakyamuni Buddha  Best Price, Shakyamuni Buddha,

Best Price, Shakyamuni Buddha,  Best Price, Shakyamuni Buddha,

Best Price, Shakyamuni Buddha,  of Shakyamuni Buddha,

of Shakyamuni Buddha,  of Shakyamuni Buddha,

of Shakyamuni Buddha,  of Amitabha Buddha In Dark Chocolate Oxidation" title="Statue

of Amitabha Buddha In Dark Chocolate Oxidation" title="Statue  of Amitabha Buddha In Dark Chocolate Oxidation" title="Statue

of Amitabha Buddha In Dark Chocolate Oxidation" title="Statue  Glossy,

Glossy,  Glossy,

Glossy,  of Amitabha Buddha

of Amitabha Buddha  of Amitabha Buddha

of Amitabha Buddha  Monastery Quality Statue

Monastery Quality Statue  Monastery Quality Statue

Monastery Quality Statue  Black Oxidized" title="Buddha Head Statue,

Black Oxidized" title="Buddha Head Statue,  Black Oxidized" title="Buddha Head Statue,

Black Oxidized" title="Buddha Head Statue,  of Medicine Buddha,

of Medicine Buddha,  of Medicine Buddha,

of Medicine Buddha,  of Shakyamuni Buddha,

of Shakyamuni Buddha,  of Shakyamuni Buddha,

of Shakyamuni Buddha,