Process: Sand Casting

This Oil Lamp has been created using the sand casting system, also known as sand molding casting. This widely employed manufacturing process utilizes a sand mold to produce metal products and components in various sizes and shapes. Sand casting holds significant popularity in the industry, accounting for approximately 60% of all metal castings. The sand casting process involves six primary steps. First, a pattern or replica of the desired sculpture, in this case, Oil Lamp, is created using a material like wood or metal. The pattern is then placed in a flask, which is a box-like structure divided into two halves. The next step involves packing the flask tightly with specially formulated molding sand, creating a mold cavity that matches the shape of the pattern. The pattern is subsequently removed, leaving behind a negative impression of the sculpture within the sand mold.

The third step is known as gating and risering, where additional channels and reservoirs are added to the mold to facilitate the flow of molten metal and compensate for any shrinkage during solidification. Once the gating system is prepared, the mold is carefully closed and secured. The fourth step involves pouring the molten metal, such as bronze or iron, into the mold through the gating system. After the metal has cooled and solidified, the mold is broken open, revealing the solid metal sculpture. The final steps involve removing any excess material, surface finishing, and polishing to achieve the desired appearance.

Sand casting offers several advantages, including its versatility in producing complex shapes, cost-effectiveness for both small and large-scale productions, and the ability to use a wide range of metals. However, it does require skilled craftsmanship and careful attention to ensure the quality and accuracy of the final sculpture. By utilizing the sand casting system, the Oil Lamp embodies the craftsmanship and artistry of the process, resulting in a captivating and unique metal artwork.

The process cycle for sand casting consists of six main stages, which are explained below

Mold-making -The first step in the sand casting process is to create the mold for the casting. In an expendable mold process, this step must be performed for each casting. A sand mold is formed by packing sand into each half of the mold. The sand is packed around the pattern, which is a replica of the external shape of the casting. When the pattern is removed, the cavity that will form the casting remains. Any internal features of the casting that cannot be formed by the pattern are formed by separate cores which are made of sand prior to the formation of the mold. Further details on mold-making will be described in the next section. The mold-making time includes positioning the pattern, packing the sand, and removing the pattern. The mold-making time is affected by the size of the part, the number of cores, and the type of sand mold. If the mold type requires heating or baking time, the mold-making time is substantially increased. Also, lubrication is often applied to the surfaces of the mold cavity in order to facilitate removal of the casting. The use of a lubricant also improves the flow the metal and can improve the surface finish of the casting. The lubricant that is used is chosen based upon the sand and molten metal temperature.

Clamping - Once the mold has been made, it must be prepared for the molten metal to be poured. The surface of the mold cavity is first lubricated to facilitate the removal of the casting. Then, the cores are positioned and the mold halves are closed and securely clamped together. It is essential that the mold halves remain securely closed to prevent the loss of any material.

Pouring - The molten metal is maintained at a set temperature in a furnace. After the mold has been clamped, the molten metal can be ladled from its holding container in the furnace and poured into the mold. The pouring can be performed manually or by an automated machine. Enough molten metal must be poured to fill the entire cavity and all channels in the mold. The filling time is very short in order to prevent early solidification of any one part of the metal.

Cooling - The molten metal that is poured into the mold will begin to cool and solidify once it enters the cavity. When the entire cavity is filled and the molten metal solidifies, the final shape of the casting is formed. The mold can not be opened until the cooling time has elapsed. The desired cooling time can be estimated based upon the wall thickness of the casting and the temperature of the metal. Most of the possible defects that can occur are a result of the solidification process. If some of the molten metal cools too quickly, the part may exhibit shrinkage, cracks, or incomplete sections. Preventative measures can be taken in designing both the part and the mold and will be explored in later sections.

Removal - After the predetermined solidification time has passed, the sand mold can simply be broken, and the casting removed. This step, sometimes called shakeout, is typically performed by a vibrating machine that shakes the sand and casting out of the flask. Once removed, the casting will likely have some sand and oxide layers adhered to the surface. Shot blasting is sometimes used to remove any remaining sand, especially from internal surfaces, and reduce the surface roughness.

Trimming - During cooling, the material from the channels in the mold solidifies attached to the part. This excess material must be trimmed from the casting either manually via cutting or sawing, or using a trimming press. The time required to trim the excess material can be estimated from the size of the casting's envelope. A larger casting will require a longer trimming time. The scrap material that results from this trimming is either discarded or reused in the sand casting process. However, the scrap material may need to be reconditioned to the proper chemical composition before it can be combined with non-recycled metal and reused.

Read More . . .

You may also want to read the related articles :

Service of Filling and blessing in Statue

|

Altering Finishing in Statue

At Handicraft Seller, we believe in providing a seamless and user-friendly experience to our valued customers. While our website is not an online shopping platform, we have incorporated a shopping cart system to simplify the process of sending us your inquiries. Please follow the steps below to place your order:

Step 1: Browsing the Selection

Explore our website to discover a delightful array of authentic Nepali handicraft products.

Click on the products you are interested in to view detailed descriptions and images.

Step 2: Adding Items to Your Inquiry Cart

To express your interest in a particular product, click the "Add to Inquiry Cart" button associated with that item.

The shopping cart will accumulate your selected products, providing a convenient way to organize your choices.

Step 3: Reviewing Your Inquiry Cart

Once you have finished selecting the items you wish to inquire about, review your "Inquiry Cart" to ensure accuracy.

Step 4: Sending Your Inquiries

Proceed to submit your inquiries by clicking the "Submit Inquiry" button.

A form will prompt you to provide your contact details, the selected products, and any specific queries you may have.

Step 5: Communicating through Email

As we do not have an automated payment system, we will conduct the business process through email.

Our team will review your inquiries and respond via email, offering further assistance and guidance.

Step 6: Clarifying Details and Finalizing Your Order

Engage in direct communication with our team to clarify any additional information or customization requests.

Once you are satisfied with the details, we will provide you with payment instructions and confirm the order.

Step 7: Completing the Transaction

Make the payment through the designated method as provided in the email.

After receiving the payment, we will process your order and prepare it for shipment.

Step 8: Shipping and Delivery

We offer worldwide shipping for all our products.

Once your order is dispatched, we will provide you with shipping details and tracking information.

Step 9: Receiving and Enjoying Your Handicrafts

Wait for your exquisite handicrafts to arrive at your doorstep.

Unpack and revel in the beauty and craftsmanship of your chosen Nepali treasures.

Contacting Us

If you encounter any complications while submitting your inquiries or need further assistance, please feel free to contact us.

Preferably, reach out to us through WhatsApp or email for prompt responses and support.

We hope this straightforward ordering process ensures a delightful and satisfying experience with Handicraft Seller. Thank you for choosing us to connect you with the rich heritage of Nepali handicrafts.

Return Policy

We have a 7 days money back policy but buyer have to pay the return shipping charges.

Shipping

- Shipping cost is calculated, based on the shipping weight of the products ordered. THe normal Shipping cost is US$25 for upto 0.5 kgs weight

- We ship Worldwide, Except Russia and India.

- The deliver duration varies for international Shipping location. We normally dispatch the product in 2 -3 business days. Else Buyer will be infromed Personally about the shipping.

This is not a direct shopping website. So no payments are needed for placing an order. Please feel free to send us an order for the product you are interested in, mentioning the approximate quantity. Based on which we will send you a wholesale price quotation.

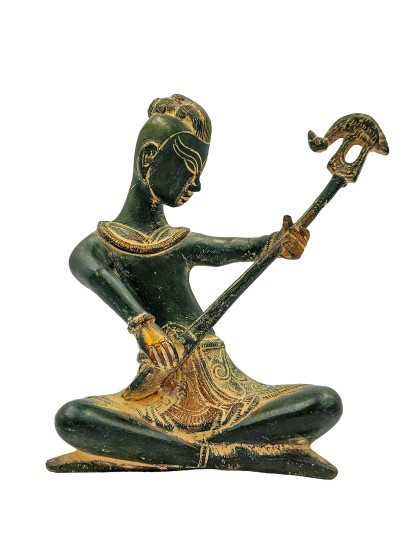

![Nepali Statue Of Oil Lamp, [sand Casting], Glossy Finishing](https://www.handmadeexpo.com/pics/product/28640.jpg)

![Nepali Statue Of Oil Lamp, [sand Casting], Glossy Finishing](https://www.handmadeexpo.com/pics/product/thumb/28640.jpg)

![Nepali Statue Of Oil Lamp, [sand Casting], Glossy Finishing](https://www.handmadeexpo.com/pics/product/thumb/28640_0.jpg)

![Nepali Statue Of Oil Lamp, [sand Casting], Glossy Finishing](https://www.handmadeexpo.com/pics/product/thumb/28640_1.jpg)

![Nepali Statue Of Oil Lamp, [sand Casting], Glossy Finishing](https://www.handmadeexpo.com/pics/product/thumb/28640_2.jpg)