Code

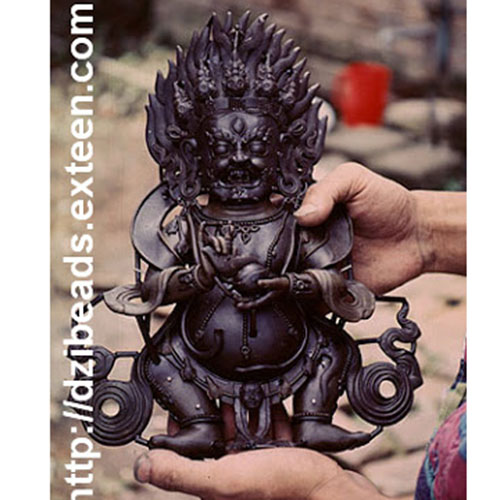

HCS12368

Weight

2 Kg / 4.41 lbs

Size

Height

30cm (12") Width

21cm (8") Depth

15cm (6") Material

Copper Gold Plated

Availability

Subject to Avilability

Date Added

2016-07-25 13:24:18

Note : We used to sell this product 9 years ago so it may no longer be in our stock.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

Safe Payment

We accept Paypal, Money Transfer, Bank Transfer

Confidence

Protection covers your purchase and personal data.

Worldwide Delivery

We ship Worldwide, except Russia.Shipping cost US$25.2 for upto 0.5 kgs

Hotline

Talk to help line for your question on 9841267335Old Post : OLD POST

Please note that this Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] is an old post. We typically do not remove our posts from the website for various reasons, such as nostalgia and maintaining page ratings. These posts are not intended for direct sales, but occasionally, we can remake the items.

Please note that this Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] is an old post. We typically do not remove our posts from the website for various reasons, such as nostalgia and maintaining page ratings. These posts are not intended for direct sales, but occasionally, we can remake the items.

Remakable : Remakable

Please note that the Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] we posted some time ago is not currently available in our store. However, due to the possibility of a remake, it is still on sale. The remake will not be an exact replica of the original statue shown in the picture and will require additional time to be ready for dispatch. If you are willing to wait for this custom remake, you may proceed with your order. Thank you for your understanding and patience.

Please note that the Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] we posted some time ago is not currently available in our store. However, due to the possibility of a remake, it is still on sale. The remake will not be an exact replica of the original statue shown in the picture and will require additional time to be ready for dispatch. If you are willing to wait for this custom remake, you may proceed with your order. Thank you for your understanding and patience.

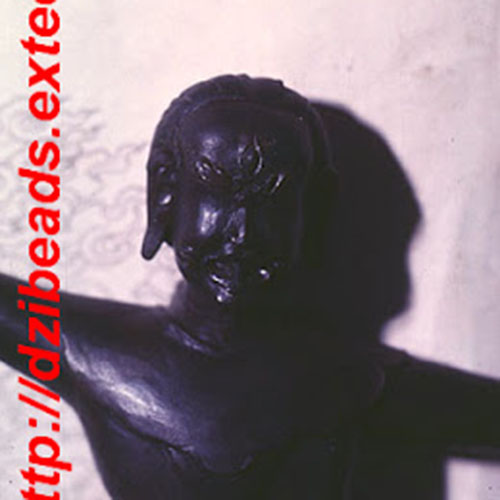

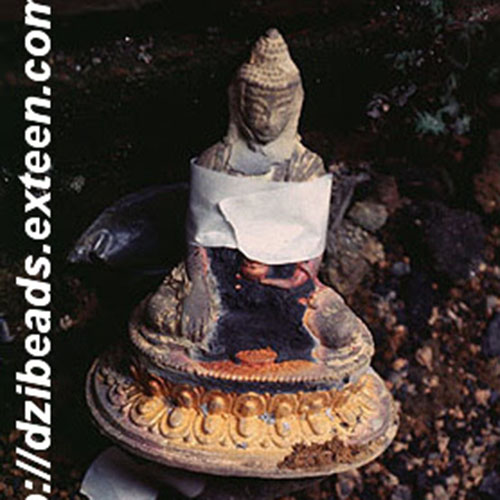

Full Fire Gold Plating

This Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] is finished with full gold plating. also known as mercury gold plating or fire gold plating. This traditional technique involves the application of a genuine layer of gold onto the Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]. Referred to as mercury gold plating, it is considered the correct and authentic form of gold plating in Nepal. Despite being more expensive than electroplating, this traditional mercury gold plating is gaining popularity again in Nepal. People are drawn to its authenticity, longevity, and the unmatched beauty it brings to the Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]. The resurgence of interest in this traditional form of gold plating reflects a growing appreciation for the craftsmanship and cultural heritage of Nepal Read More . . .

This Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] is finished with full gold plating. also known as mercury gold plating or fire gold plating. This traditional technique involves the application of a genuine layer of gold onto the Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]. Referred to as mercury gold plating, it is considered the correct and authentic form of gold plating in Nepal. Despite being more expensive than electroplating, this traditional mercury gold plating is gaining popularity again in Nepal. People are drawn to its authenticity, longevity, and the unmatched beauty it brings to the Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]. The resurgence of interest in this traditional form of gold plating reflects a growing appreciation for the craftsmanship and cultural heritage of Nepal Read More . . .

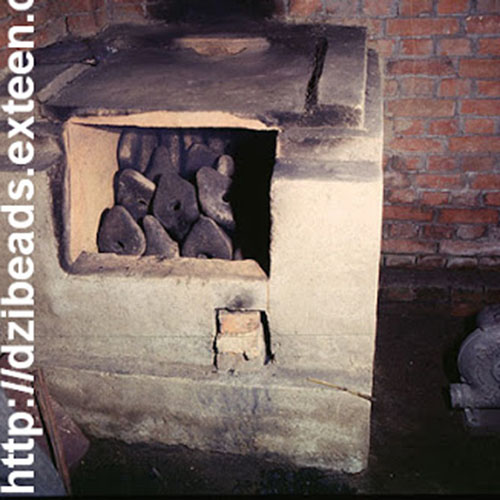

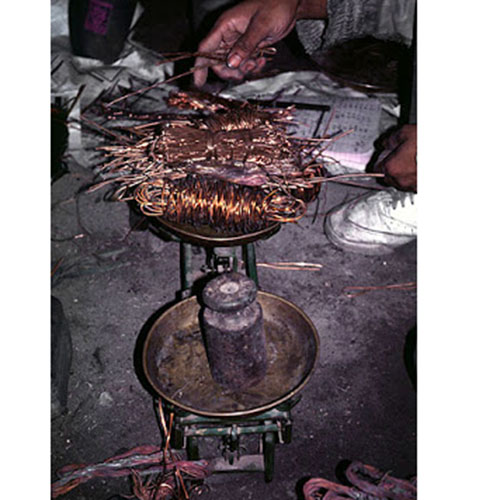

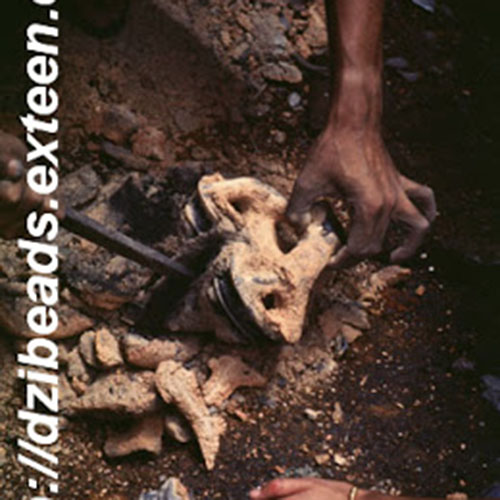

Lost-Wax System

This Yamantaka of Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Yamantaka.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

This Yamantaka of Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Yamantaka.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

Brief Introduction :

OM AH RA PA TSA NA DHIH

Yama represents the end of one cycle & beginning of another. The deity Yama is wrathful to try to encourage you not to return to a previous cycle or habit. He is there to help you break the cyclical nature of existence [Skt. Samsara so that you can access the higher realm of human consciousness. He is fed up with the attachment of mankind to the Five negative afflictions [Skt. Kleashas] if pushed he has the authority to send you at your physical death to a place of ice & fire.

Iconography :The five skulls on Yama's diadem represent the Five Negative Affliction Or poisonous Buddhsit_Art_Yamaobstacles [Skt. Kleshas] to spiritual development which are greed, hatred, delusion, jealousy & pride & the transmutation of the five afflictions into the five wisdoms. His special power to change the five troubles is indicated by the tongues of crimson flame that arise from the cranium of each skull. He is painted with a bull's head, and he straddles a blue boar which crushes a human form. In his left hand in the threatening hand position [Skt. Tarjani Mudra] Yama brandishes a skull club [Skt. Kapala Danda] also carried by Kali [Shiva] & Bhairav that symbolises "smashing the veil of ignorance" and the ultimate emptiness of all phenomena which we need to realise the highest Buddhist ideal of Great Bliss [Skt. Mahasukha], pure consciousness and love. The energy is so powerful that it is sealed with a half vajra at the top. The white silk ribbons represents his ability adapt his energy to destroy ignorance in all its forms. In his right hand he holds a rope noose [Skt. Pasha] . One end has a hook and the other a ring which representing the catching & binding of the ego, the possibility of strangulation.

His sister Yami holds a skullcap [Skt. Kapala] held at his heart in his right hand hold red rejuvenating blood of Great Bliss called Raktavarna[skt.] representing 'wisdom'. The white breast ornament represents the wheel of life [Skt. Jivan Chakra] Jivan is a Sanskrit word meaning soul. Chakra means wheel. The wheel of Life is often called the Bhavacakra. Bhava means container or receptacle in the sense of body or form. The degree of wrath & and tantric power a deity has is often measured by the quantity of flame in the aureole of flame surrounding body. Yama is surrounded by a Fire Wheel [Tib. Me-Khor] which represents his ability to annihilate anything or anyone that crosses his path, but especially the obscuration to pure conscious enlightenment of which ignorance is considered the chief poison. The fire wheel radiate as pure psychic energy whose potency is alluded to in Yama's erect penis. Nothing can withstand Yama's fire wheel. In the foreground there are the Three Skull Offerings which represent the items necessary for rebirth. The left & right skulls are traditionally mounted on three smaller skulls. The left blue blood represents semen & the right red blood fertile uterine blood with the central skull contains the offering of the five senses representing the consciousness. The five senses are 1. the heart representing touch, 2. the eyes - sight, 3. tongue - taste, 4. nose - smell & 5. ears - sound. The attached hair indicates its freshness. The offering of the five senses is key to Yama's purpose; the offering is about rebirth the beginning of something new life.

Commentary :His sister Yami holds a skullcap [Skt. Kapala] held at his heart in his right hand hold red rejuvenating blood of Great Bliss called Raktavarna[skt.] representing 'wisdom'. The white breast ornament represents the wheel of life [Skt. Jivan Chakra] Jivan is a Sanskrit word meaning soul. Chakra means wheel. The wheel of Life is often called the Bhavacakra. Bhava means container or receptacle in the sense of body or form. The degree of wrath & and tantric power a deity has is often measured by the quantity of flame in the aureole of flame surrounding body. Yama is surrounded by a Fire Wheel [Tib. Me-Khor] which represents his ability to annihilate anything or anyone that crosses his path, but especially the obscuration to pure conscious enlightenment of which ignorance is considered the chief poison. The fire wheel radiate as pure psychic energy whose potency is alluded to in Yama's erect penis. Nothing can withstand Yama's fire wheel. In the foreground there are the Three Skull Offerings which represent the items necessary for rebirth. The left & right skulls are traditionally mounted on three smaller skulls. The left blue blood represents semen & the right red blood fertile uterine blood with the central skull contains the offering of the five senses representing the consciousness. The five senses are 1. the heart representing touch, 2. the eyes - sight, 3. tongue - taste, 4. nose - smell & 5. ears - sound. The attached hair indicates its freshness. The offering of the five senses is key to Yama's purpose; the offering is about rebirth the beginning of something new life.

Yama is an ancient Vedic deity. His name comes from the root Ya meaning 'twin' in the sense of to restrain or bound. In Tibet Yama is usually Dam Can Chos rGyal, 'The Pledge Bound Dharma-King'. The later alludes to his conversion to Buddhism by Manjusri, the Bodhisattva of Wisdom in his wrathful manifestation as Yamantaka 'the Destroyer of Yama". There are three common forms of Yama that occur in Tibetan Buddhism which are called respectively the External, Internal, and Secrete Yama. This painting depicts the External or Outer form of Yama who is a Dharma protector invoked to protect devotees from mundane difficulties such as physical illness and hunger. He is the colour blue and is shown in the characteristic fierce standing pose of a protective deity with a pot belly and erect penis. He has the head of a fierce bull with sharply pointed horns and protruding blood shot eyeballs. The bull is an ancient symbol in Indic religions that is associated with Yama and death, but also can symbolize procreation. This ambivalent symbolism is understood in the Buddhist context as the overcoming of death to create eternal life. Yama is personified as a bull as a metaphor of the uncontrolled mind that one must learn to control to overcome death. In his role as lord of hell, Yama should not be confused with Western religious notions of the Devil as the embodiment of evil but as a deity given a task within the greater Buddhist cause of the salvation of all living beings. In Buddhist symbolic terms the overcoming of death by terminating the cycle of rebirth is the ultimate goal and it is Yama who serves as a transformer in that process by embodying impermanence.

Mantra of Yamantaka

OM AH RA PA TSA NA DHIH

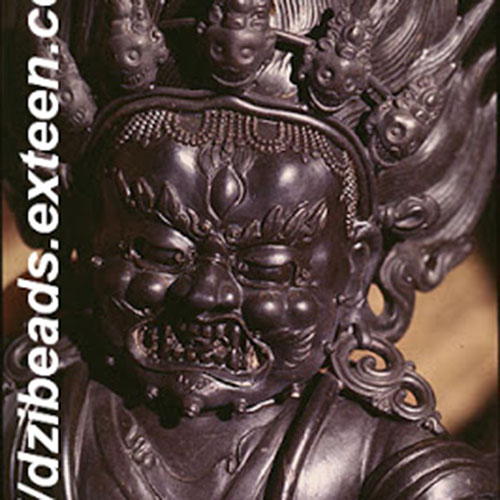

![Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2016/07/12368.jpg)

![Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2016/07/12368_0.jpg)

![Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2016/07/12368_1.jpg)

![Yamantaka - Heruka Statue: Full Fire Gold Plated, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2016/07/12368_2.jpg)

Yamantaka, Buddhist Handmade Statue,

Yamantaka, Buddhist Handmade Statue,  Yamantaka, Buddhist Handmade Statue,

Yamantaka, Buddhist Handmade Statue,  of Yamantaka Vajrabhairava- Heruka,

of Yamantaka Vajrabhairava- Heruka,  of Yamantaka Vajrabhairava- Heruka,

of Yamantaka Vajrabhairava- Heruka,  Rare Find,

Rare Find,  Rare Find,

Rare Find,  of Yamantaka Vajrabhairava- Heruka

of Yamantaka Vajrabhairava- Heruka  of Yamantaka Vajrabhairava- Heruka

of Yamantaka Vajrabhairava- Heruka  Yamantaka, Tibetan Statue,

Yamantaka, Tibetan Statue,  Yamantaka, Tibetan Statue,

Yamantaka, Tibetan Statue,  Yamantaka Shakti, Buddhist Handmade Statue,

Yamantaka Shakti, Buddhist Handmade Statue,  Yamantaka Shakti, Buddhist Handmade Statue,

Yamantaka Shakti, Buddhist Handmade Statue,  Yamantaka

Yamantaka  Yamantaka

Yamantaka  of Yamantaka, Full Gold Plated,

of Yamantaka, Full Gold Plated,  of Yamantaka, Full Gold Plated,

of Yamantaka, Full Gold Plated,  of Yamantaka - Vajrabhairava Heruka Megha Sambara,

of Yamantaka - Vajrabhairava Heruka Megha Sambara,  of Yamantaka - Vajrabhairava Heruka Megha Sambara,

of Yamantaka - Vajrabhairava Heruka Megha Sambara,  of Yamantaka Vajrabhairava- Heruka,

of Yamantaka Vajrabhairava- Heruka,  of Yamantaka Vajrabhairava- Heruka,

of Yamantaka Vajrabhairava- Heruka,