Code

HCS10186

Weight

7 Kg / 15.43 lbs

Size

Height

44cm (17") Width

31cm (12") Depth

22cm (9") Material

copper

Availability

Sold

Date Added

2014-01-23 17:39:33

Note : We used to sell this product 11 years ago so it may no longer be in our stock.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

Safe Payment

We accept Paypal, Money Transfer, Bank Transfer

Confidence

Protection covers your purchase and personal data.

Worldwide Delivery

We ship Worldwide, except Russia.Shipping cost US$25.2 for upto 0.5 kgs

Hotline

Talk to help line for your question on 9841267335About sold

this item is sold

this item is sold

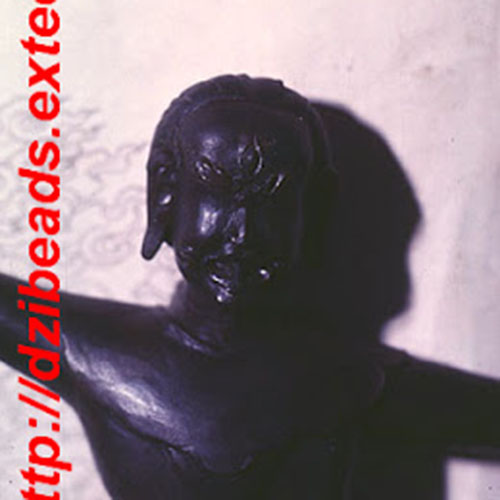

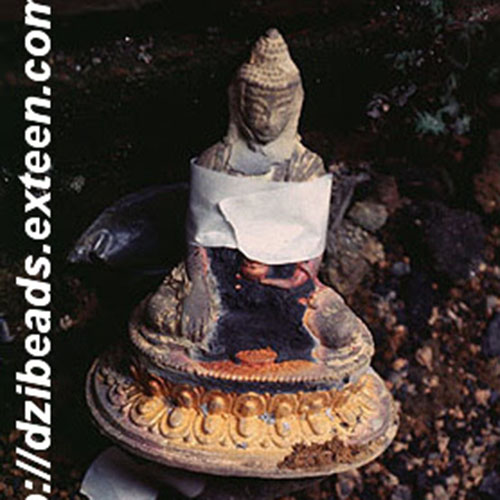

What is Stone Color

This Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold] is finished in a stunning Stone color finishing. This finish offers several advantages, allowing you to experience the feel of a stone statue while benefiting from the durability and detailed craftsmanship of copper. By choosing the Stone color finishing, you can enjoy the aesthetic appeal of a stone statue. This finish replicates the texture and appearance of stone, bringing a natural and organic touch to Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]. It creates a visually pleasing effect that adds depth and character to the piece. Read More . . .

This Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold] is finished in a stunning Stone color finishing. This finish offers several advantages, allowing you to experience the feel of a stone statue while benefiting from the durability and detailed craftsmanship of copper. By choosing the Stone color finishing, you can enjoy the aesthetic appeal of a stone statue. This finish replicates the texture and appearance of stone, bringing a natural and organic touch to Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]. It creates a visually pleasing effect that adds depth and character to the piece. Read More . . .

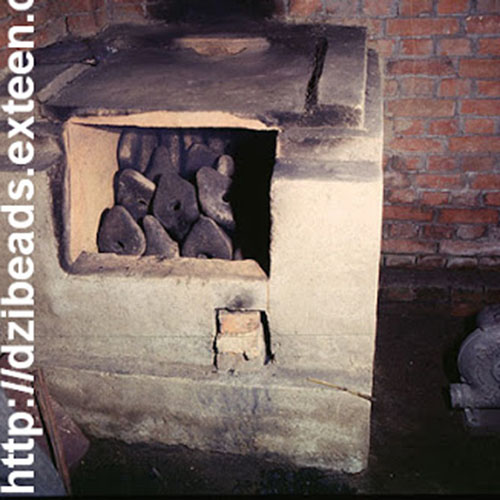

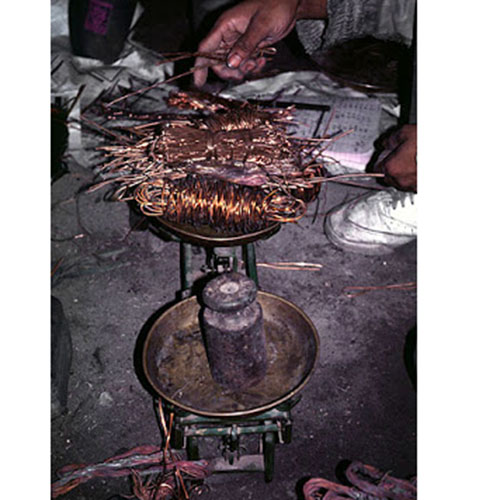

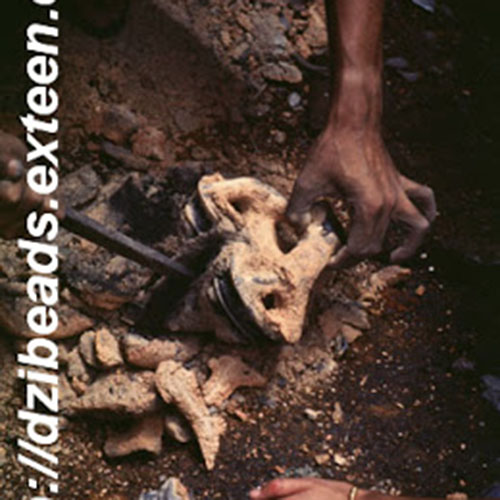

Lost-Wax System

This Others of Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Others.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

This Others of Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Others.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

Brief Introduction :

Indra is the King of the demi-gods or Devas and Lord of Heaven Hindu mythology. He is also the God of War, Storms, and Rainfall.

Indra is one of the chief deities in the Rigveda. He is celebrated as a demiurge who pushes up the sky, releases dawn (Ushas) from the Vala cave, and slays Vṛtra; both latter actions are central to the Soma sacrifice. On the other hand, he also commits (like Zeus) many kinds of mischief (kilbiṣa) for which he is sometimes punished. He has many epithets, notably vṛṣan the bull, and vṛtrahan, slayer of Vṛtra and maghavan "the bountiful'. Indra appears as the name of an arch-demon in the Zoroastrian religion, while his epithet Verethragna appears as a god of victory.

In Puranic mythology, Indra is bestowed with a heroic and almost brash and amorous character at times, even as his reputation and role diminished in later Hinduism with the rise of the Trimurti. Indra is also called Śakra frequently in the Vedas and in Buddhism.

Budddhist Definition :Indra is one of the chief deities in the Rigveda. He is celebrated as a demiurge who pushes up the sky, releases dawn (Ushas) from the Vala cave, and slays Vṛtra; both latter actions are central to the Soma sacrifice. On the other hand, he also commits (like Zeus) many kinds of mischief (kilbiṣa) for which he is sometimes punished. He has many epithets, notably vṛṣan the bull, and vṛtrahan, slayer of Vṛtra and maghavan "the bountiful'. Indra appears as the name of an arch-demon in the Zoroastrian religion, while his epithet Verethragna appears as a god of victory.

In Puranic mythology, Indra is bestowed with a heroic and almost brash and amorous character at times, even as his reputation and role diminished in later Hinduism with the rise of the Trimurti. Indra is also called Śakra frequently in the Vedas and in Buddhism.

In Buddhism and Jainism, Indra is commonly called by his other name, Śakra or Sakka, ruler of the Trāyastriṃśa heaven. However, Śakra is sometimes given the title Indra, or, more commonly, Devānām Indra, "Lord of the Devas". The ceremonial name of Bangkok claims that the city was "given by Indra and built by Vishvakarman." The provincial seal of Surin Province, Thailand is an image of Indra atop Airavata.

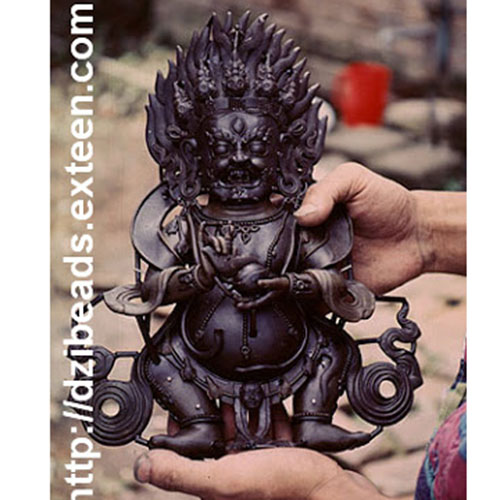

![Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]](https://handicraftseller.com/uploads/pics/product/thumb/2014/01/10186.jpg)

![Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]](https://handicraftseller.com/uploads/pics/product/thumb/2014/01/10186_0.jpg)

![Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]](https://handicraftseller.com/uploads/pics/product/thumb/2014/01/10186_1.jpg)

![Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]](https://handicraftseller.com/uploads/pics/product/thumb/2014/01/10186_2.jpg)

![Statue Of Indra Stone Color Finishing Statue, [stone Finishing], [sold]](https://handicraftseller.com/uploads/pics/product/thumb/2014/01/10186_3.jpg)

Phurba, Buddhist Handmade,

Phurba, Buddhist Handmade,  Phurba, Buddhist Handmade,

Phurba, Buddhist Handmade,  Padmapani Lokeshvara, Buddhist Handmade Statue,

Padmapani Lokeshvara, Buddhist Handmade Statue,  Padmapani Lokeshvara, Buddhist Handmade Statue,

Padmapani Lokeshvara, Buddhist Handmade Statue,  Padmapani Lokeshvara, Buddhist Handmade Statue,

Padmapani Lokeshvara, Buddhist Handmade Statue,  Padmapani Lokeshvara, Buddhist Handmade Statue,

Padmapani Lokeshvara, Buddhist Handmade Statue,  of Naga Kanya

of Naga Kanya  of Naga Kanya

of Naga Kanya  Palden Lahmo, Buddhist Handmade Statue,

Palden Lahmo, Buddhist Handmade Statue,  Palden Lahmo, Buddhist Handmade Statue,

Palden Lahmo, Buddhist Handmade Statue,  of Dancing Shiva, Mahadev, Nataraja,

of Dancing Shiva, Mahadev, Nataraja,  of Dancing Shiva, Mahadev, Nataraja,

of Dancing Shiva, Mahadev, Nataraja,  Manjushri, Buddhist Handmade Statue,

Manjushri, Buddhist Handmade Statue,  Manjushri, Buddhist Handmade Statue,

Manjushri, Buddhist Handmade Statue,  Aparimita, Buddhist Handmade Statue,

Aparimita, Buddhist Handmade Statue,  Aparimita, Buddhist Handmade Statue,

Aparimita, Buddhist Handmade Statue,  Hevajra, Buddhist Handmade Statue,

Hevajra, Buddhist Handmade Statue,  Hevajra, Buddhist Handmade Statue,

Hevajra, Buddhist Handmade Statue,  Namgyalma, Buddhist Handmade Statue,

Namgyalma, Buddhist Handmade Statue,  Namgyalma, Buddhist Handmade Statue,

Namgyalma, Buddhist Handmade Statue,