Code

HCS10324

Weight

1.3 Kg / 2.87 lbs

Size

Height

20cm (8") Width

14cm (6") Depth

10cm (4") Material

copper full gold plated

Availability

Subject to Avilability

Date Added

2014-02-11 10:20:00

Note : We used to sell this product 11 years ago so it may no longer be in our stock.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

It is possible that we still have it with our suppliers but the price could be different from before.

Feel free to order. We will verify availability and inform you promptly.

Safe Payment

We accept Paypal, Money Transfer, Bank Transfer

Confidence

Protection covers your purchase and personal data.

Worldwide Delivery

We ship Worldwide, except Russia.Shipping cost US$25.2 for upto 0.5 kgs

Hotline

Talk to help line for your question on 9841267335Old Post : OLD POST

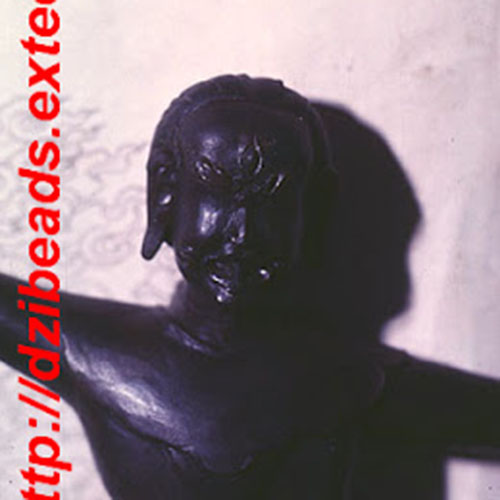

Please note that this Milarepa, [old Post], [remakable] is an old post. We typically do not remove our posts from the website for various reasons, such as nostalgia and maintaining page ratings. These posts are not intended for direct sales, but occasionally, we can remake the items.

Please note that this Milarepa, [old Post], [remakable] is an old post. We typically do not remove our posts from the website for various reasons, such as nostalgia and maintaining page ratings. These posts are not intended for direct sales, but occasionally, we can remake the items.

Remakable : Remakable

Please note that the Milarepa, [old Post], [remakable] we posted some time ago is not currently available in our store. However, due to the possibility of a remake, it is still on sale. The remake will not be an exact replica of the original statue shown in the picture and will require additional time to be ready for dispatch. If you are willing to wait for this custom remake, you may proceed with your order. Thank you for your understanding and patience.

Please note that the Milarepa, [old Post], [remakable] we posted some time ago is not currently available in our store. However, due to the possibility of a remake, it is still on sale. The remake will not be an exact replica of the original statue shown in the picture and will require additional time to be ready for dispatch. If you are willing to wait for this custom remake, you may proceed with your order. Thank you for your understanding and patience.

About Elector Gold Plating

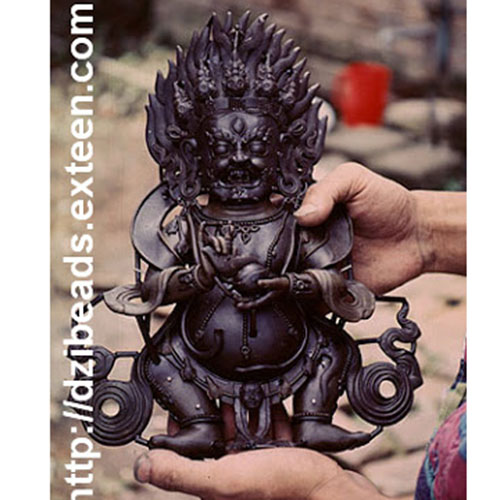

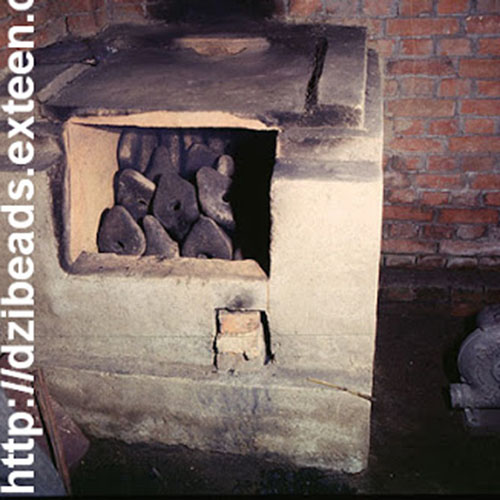

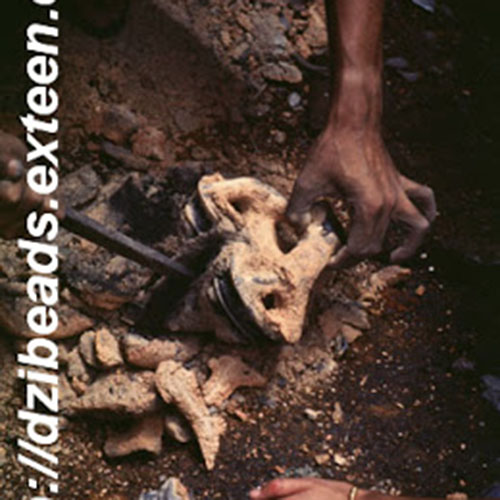

The Milarepa, [old Post], [remakable] has been crafted using the ceramic mold casting process, a modern approach that provides an alternative to traditional methods such as the lost-wax system or rubber molding. Also referred to as ceramic molding, this technique involves the creation of a ceramic mold to cast the statue. The process begins by making a precise and detailed wax model of the desired sculpture. The wax model is then coated with layers of ceramic material, creating a sturdy mold. Once the mold is complete, it is fired in a kiln, causing the wax to melt and escape, leaving behind a cavity that perfectly replicates the original sculpture. Molten metal is then poured into the mold, allowing it to fill the cavity and take on the desired form. Once cooled and solidified, the ceramic mold is carefully broken away, revealing the final metal statue. Read More . . .

The Milarepa, [old Post], [remakable] has been crafted using the ceramic mold casting process, a modern approach that provides an alternative to traditional methods such as the lost-wax system or rubber molding. Also referred to as ceramic molding, this technique involves the creation of a ceramic mold to cast the statue. The process begins by making a precise and detailed wax model of the desired sculpture. The wax model is then coated with layers of ceramic material, creating a sturdy mold. Once the mold is complete, it is fired in a kiln, causing the wax to melt and escape, leaving behind a cavity that perfectly replicates the original sculpture. Molten metal is then poured into the mold, allowing it to fill the cavity and take on the desired form. Once cooled and solidified, the ceramic mold is carefully broken away, revealing the final metal statue. Read More . . .

Lost-Wax System

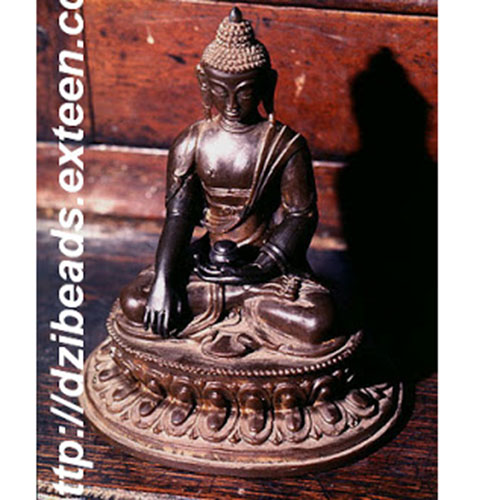

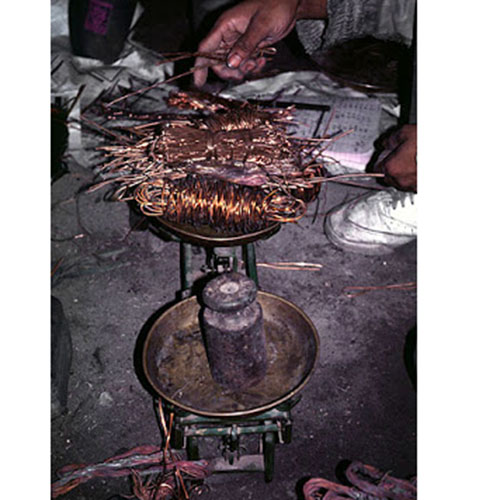

This Milarepa of Milarepa, [old Post], [remakable] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Milarepa.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

This Milarepa of Milarepa, [old Post], [remakable] is made by the process of the Lost Wax system. This is a very complicated, time consuming and historic process of making metal sculptures.Which is why it is sometimes called Precision Casting as well. Hence the sculptures made by this process are comparatively expensive. There are many new, advanced and less time consuming methods of casting metal sculptures available as well. But due to the benefits provided by the traditional lost wax system in quality control and customization, we prefer the Loss wax system over Ceramic molding, or sand casting to make our Milarepa.

Below we have tried to illustrate the process of making a loss wax system statue: Read More . . .

Brief Introduction :

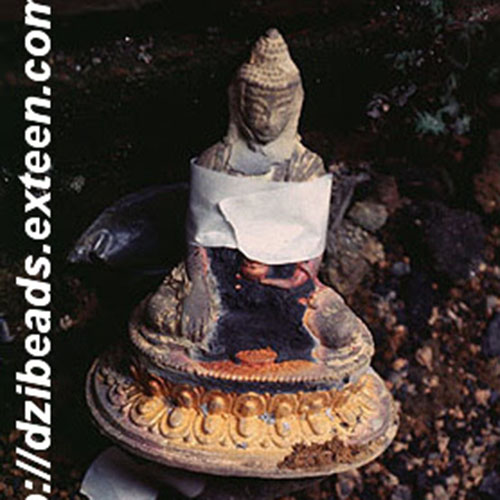

Milarepa is one of the most widely known Tibetan Saints. In a superhuman effort, he rose above the miseries of his younger life and with the help of his Guru, Marpa the Translator, took to a solitary life of meditation until he had achieved the pinnacle of the enlightened state, never to be born again into the Samsara (whirlpool of life and death) of worldly existence. Out of compassion for humanity, he undertook the most rigid asceticism to reach the Buddhic state of enlightenment and to pass his accomplishments on to the rest of humanity. His spiritual lineage was passed along to his chief disciples, Gambopa and Rechung. It was Rechung who recorded in detail the incidents of Milarepa's life for posterity. The narrative of his life has thus been passed down through almost a millennium of time and has become an integral part of Tibetan culture. In addition to Rechung's narrative of his life, summarized below, Milarepa extemporaneously composed innumerable songs throughout his life relevant to the dramatic turns of events of himself and his disciples in accordance with an art form that was in practice at the time. These songs have been widely sung and studied in Tibet ever since and have been recorded as the Hundred Thousand Songs of Milarepa. His faithful devotion, boundless religious zeal, monumental forbearance, superhuman perseverance, and ultimate final attainment are a great inspiration today for all. His auspicious life illumined the Buddhist faith and brought the light of wisdom to sentient beings everywhere.

Iconography :Milarepa is mostly seen sitted

Life Story :Born in the village of Kya Ngatsa - also known as Tsa - in Gungthang province of western Tibet to a prosperous family he was named Mila Thöpaga (Thos-pa-dga'), which means "A joy to hear." His family name, Josay indicates noble descent, a sept of the Khyungpo or eagle clan. When his father died, Milarepa's uncle and aunt took all of the family's wealth. At his mother's request, Milarepa left home and studied sorcery. While his aunt and uncle were having a party to celebrate the impending marriage of their son, he took his revenge by summoning a giant hail storm to demolish their house, killing 35 people, although the uncle and aunt are supposed to have survived. The villagers were angry and set off to look for Milarepa, but his mother got word to him and he sent a hailstorm to destroy their crops.

Many of Milarepa's deeds took place in Chokyi Dronma's homeland and his life and songs were compiled by Tsangnyon Heruka, sponsored by Chokyi Dronma's brother, the Gungthang king Thri Namgyal De.

Milarepa later lamented his evil ways in his older years: "In my youth I committed black deeds. In maturity I practiced innocence. Now, released from both good and evil, I have destroyed the root of karmic action and shall have no reason for action in the future. To say more than this would only cause weeping and laughter. What good would it do to tell you? I am an old man. Leave me in peace."

Linage :Many of Milarepa's deeds took place in Chokyi Dronma's homeland and his life and songs were compiled by Tsangnyon Heruka, sponsored by Chokyi Dronma's brother, the Gungthang king Thri Namgyal De.

Milarepa later lamented his evil ways in his older years: "In my youth I committed black deeds. In maturity I practiced innocence. Now, released from both good and evil, I have destroyed the root of karmic action and shall have no reason for action in the future. To say more than this would only cause weeping and laughter. What good would it do to tell you? I am an old man. Leave me in peace."

Milarepa is famous for many of his songs and poems, in which he expresses the profundity of his realization of the dharma. He also had many disciples, male and female, including Rechung Dorje Drakpa (Ras-chung Rdo-rje Grags-pa) and Gampopa (Sgam-po-pa, Dhakpo Lhaje). His female disciples include Rechungma, Padarbum, Sahle Aui and Tsheringma.It was Gampopa who became Milarepa's spiritual successor, continued his lineage, and became one of the main lineage masters in Milarepa's tradition.

Mantra of Milarespa

Om Ah Guru Hasa Vajra Hung

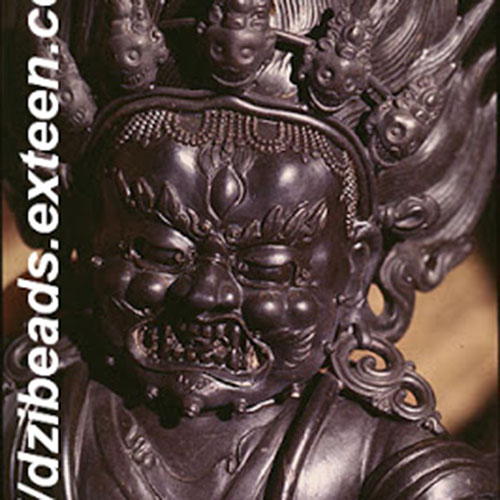

![Milarepa, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2014/02/10324.jpg)

![Milarepa, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2014/02/10324_0.jpg)

![Milarepa, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2014/02/10324_1.jpg)

![Milarepa, [old Post], [remakable]](https://handicraftseller.com/uploads/pics/product/thumb/2014/02/10324_2.jpg)

of Karmapa,

of Karmapa,  of Karmapa,

of Karmapa,  Old Post,

Old Post,  of Milarepa,

of Milarepa,  of Milarepa,

of Milarepa,  Old Post,

Old Post,  Old Post,

Old Post,  Old Post,

Old Post,  of Marpa Lotsawa,

of Marpa Lotsawa,  of Marpa Lotsawa,

of Marpa Lotsawa,  of Milarepa,

of Milarepa,  of Milarepa,

of Milarepa,  Milarepa, Buddhist Handmade Statue,

Milarepa, Buddhist Handmade Statue,  Milarepa, Buddhist Handmade Statue,

Milarepa, Buddhist Handmade Statue,  of Milarepa,

of Milarepa,  of Milarepa,

of Milarepa,  of

of  of

of